Custom Apparel Manufacturer Mumbai

We Don’t Just Print Shirts. We Engineer Identities. Noble Custom Prints: Mumbai’s Premier Direct-to-Consumer Apparel Factory.

1. The Introduction

At Noble Custom Prints, we believe that great teams deserve great gear. Located at Mumbai, we are a full-service apparel manufacturer dedicated to producing high-quality custom sportswear, corporate uniforms, and promotional merchandise.

Unlike trading companies or middlemen who outsource production, we own our manufacturing line. From the initial fabric cutting to the final embroidery stitch, every stage of production happens under our supervision. This “Factory-Direct” approach allows us to offer three things our competitors can’t: Lower Wholesale Pricing, Faster Turnaround Times, and Uncompromising Quality Control.

2. Our Expertise

We specialize in end-to-end garment construction. We don’t just print on blank t-shirts; we build them from scratch.

- Custom Sportswear: Engineering high-performance Cricket Jerseys, Football Kits, and Track Pants using premium dri-fit and imported spandex polyester fabric.

- Corporate Identity: Manufacturing premium Polos, Hoodies, and Caps that elevate your brand image.

- Textile Innovation: Sourcing the finest fabrics—from heavy 330 GSM Cotton Fleece for winters to imported light weight Stretch Spandex for sportswear.

3. Why Choose Noble Custom Prints?

A. Advanced Manufacturing Technology Our facility is equipped with state-of-the-art machinery to handle diverse customization needs:

- Full Sublimation Units: For 3D, all-over printing that never fades.

- Industrial Vinyl Cutter: For precise, high-definition logos on caps and polos.

- Screen & DTF Printing Setup: For vibrant, cost-effective bulk branding.

B. No Limits Customization We believe in total freedom. You choose the fabric, the GSM, the collar style, the sleeve length, and the fit. If you can design it, we can stitch it.

C. Scalability Whether you are a startup needing 50 t-shirts or a multinational corporation requiring 5,000 uniforms, our production line scales to meet your deadlines without sacrificing quality.

4. Our Mission

To empower Indian teams, businesses, and brands with retail-quality custom apparel that instills pride and unity. We are committed to proving that “Made in India” stands for world-class craftsmanship.

5. Quality, Made Locally

Come Visit Our Factory Transparency is our policy. We invite clients to visit our unit in Mulund Mumbai to see our production quality firsthand.

Real Machines. Real Production. No Outsourcing.

At Noble Custom Prints, we take pride in being the most reliable Custom Apparel Manufacturer Mumbai, dedicated to bridging the gap between industrial production and personalized service. While many suppliers claim to be a Custom Apparel Manufacturer Mumbai, they are often just traders outsourcing your order; we are different because we operate our own factory in Thane with complete Cut & Sew capabilities. As a vertically integrated Custom Apparel Manufacturer Mumbai, we control every stage of production, from knitting heavy GSM fabrics for Winter Hoodies to precision Sublimation for Sports Jerseys. Our status as a premier Custom Apparel Manufacturer Mumbai allows us to offer factory-direct pricing on Corporate Uniforms and promotional T-shirts without compromising on quality.

We utilize advanced Epson printing technology and industrial embroidery units, setting a standard that other Custom Apparel Manufacturer Mumbai entities struggle to match. Whether you need bulk Election Campaign gear or premium startup merchandise, partnering with a genuine Custom Apparel Manufacturer Mumbai ensures your deadlines are met with precision. We understand that your brand reputation depends on the quality of your merchandise, which is why we have established ourselves as the Custom Apparel Manufacturer Mumbai that prioritizes durability and fabric integrity. Choose Noble Custom Prints today and experience the professional advantage of working with a dedicated Custom Apparel Manufacturer Mumbai • Share Your Requirements

From stitching to finishing, we control every step of the process.

The Cut & Sew Unit: Where Quality Begins

Precision Tailoring, Not Just Assembly: At Noble Custom Prints, we don’t buy ready-made blanks; we build your apparel from the fabric up. Our dedicated Stitching & Cutting Unit is the heart of our factory, equipped with industrial-grade sewing machines and large-format cutting tables.

The Advantage: Whether it’s reinforcing the seams on a cricket jersey or adding double-stitching to a corporate hoodie, our in-house control allows us to customize the fit and durability exactly to your specifications. No loose threads, no sizing errors—just perfect construction.

The Process: Skilled masters hand-cut heavy GSM fabrics to ensure consistent sizing for every S, M, and XL.

Design & Digital Sublimation Lab

From Screen to Fabric: High-Definition Vibrancy: This is where your vision turns into reality. Our Design & Printing Unit houses a team of expert graphic designers working side-by-side with our advanced Imported Sublimation Printers.

The Advantage: By keeping design and printing under one roof, we eliminate communication gaps. We can spot color mismatches instantly and ensure that the ‘Royal Blue’ on your screen is the exact ‘Royal Blue’ that prints on your jersey.

The Process: Our designers first optimize your vector files for sharpness. Then, our high-speed digital printers transfer these designs onto specialized sublimation paper using premium fade-proof inks.

The Fusing & Heat Transfer Station

Locking in the Color: Permanent Performance: Printing is only half the battle; curing is where the magic happens. Our Fusing Unit features industrial large-format flatbed heat presses and specialized cap-press machines.

The Advantage: This ensures your sports jerseys remain breathable and the designs never crack, peel, or fade, even after 100 washes. From full-kit jerseys to custom branded caps, this unit ensures your branding is permanent.

The Process: We subject the printed sublimation paper and fabric to 200°C+ temperatures. This “fuses” the ink directly into the fabric fibers, turning it from a liquid state to a permanent gas infusion.

Industrial Screen Printing Unit

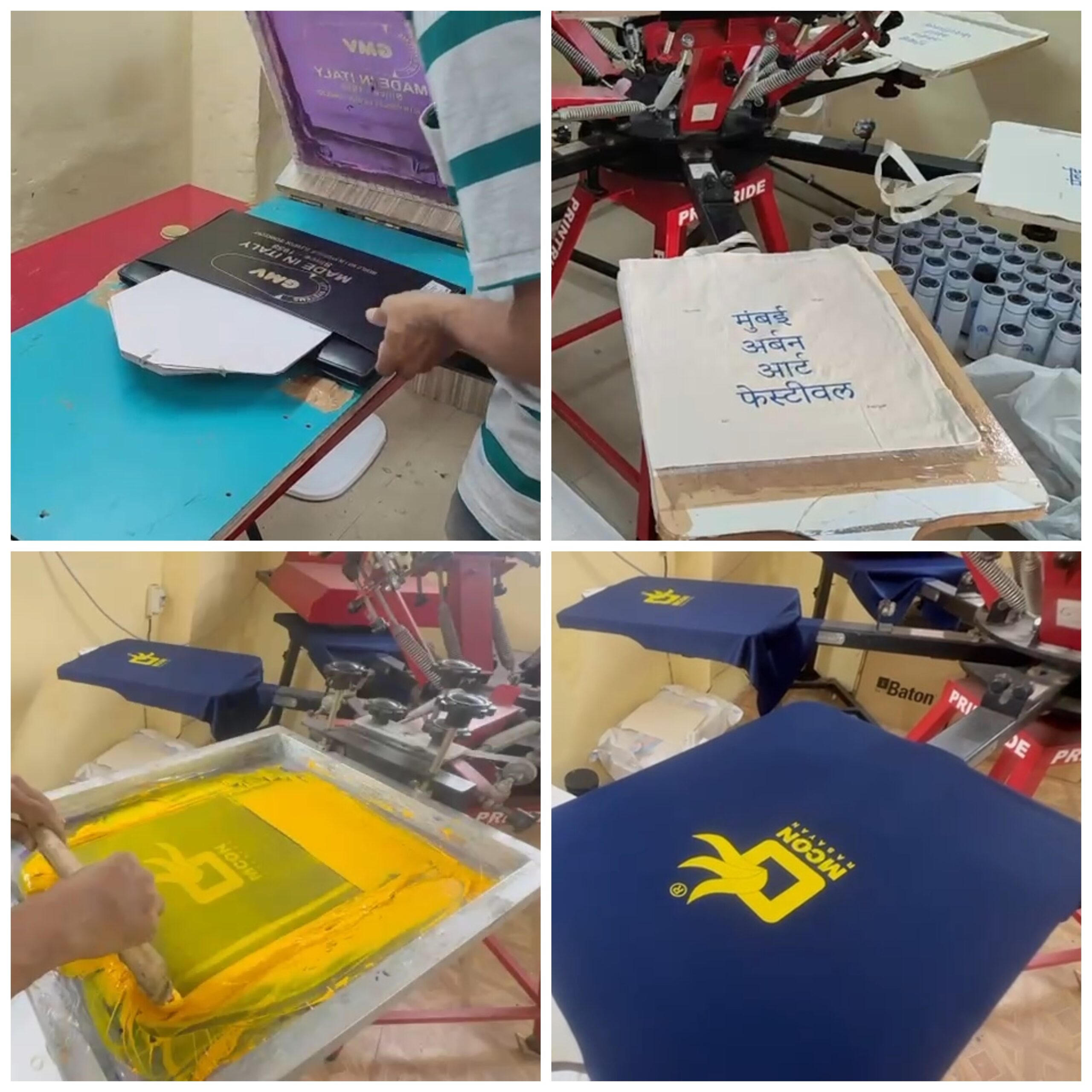

Bold, Texture-Rich Branding for Corporate Identity: For cotton t-shirts and corporate uniforms, nothing beats the classic durability of screen printing. Our Screen Printing Unit features a heavy-duty 6-station carousel setup capable of handling multi-color jobs with laser precision.

The Advantage: This method delivers that premium “raised” feel and bold color opacity that corporate clients love. It is the gold standard for durability on cotton round-necks, hoodies, and tote bags.

The Process: We create individual mesh screens for every color in your logo. High-opacity plastisol inks are pushed through these screens to create a thick, vibrant layer on top of the fabric.

Precision Vinyl Cut & Heat Transfer

Sharp, Personalized Branding with Zero Minimums: For individual names, jersey numbers, and intricate single-color logos, we utilize our specialized Vinyl Transfer Studio. This unit is powered by the GCC Jaguar V LX cutting plotter, known for its ability to cut hairline curves with absolute accuracy.

The Process: The digital plotter precisely cuts your design into high-quality polyurethane vinyl. Our technicians then meticulously “weed” (remove) the excess material by hand before heat-pressing the design onto the garment. As seen in our workshop, this method allows for clean, crisp application even on textured fabrics like pique polos.

The Advantage: Vinyl is the ultimate solution for Personalization. Unlike screen printing, which requires expensive setup for every change, vinyl allows us to print “Name: Rahul” on one shirt and “Name: Amit” on the next without extra cost. It offers a premium matte or glossy finish that sits smoothly on the fabric, making it perfect for corporate branding and sports jersey numbering.