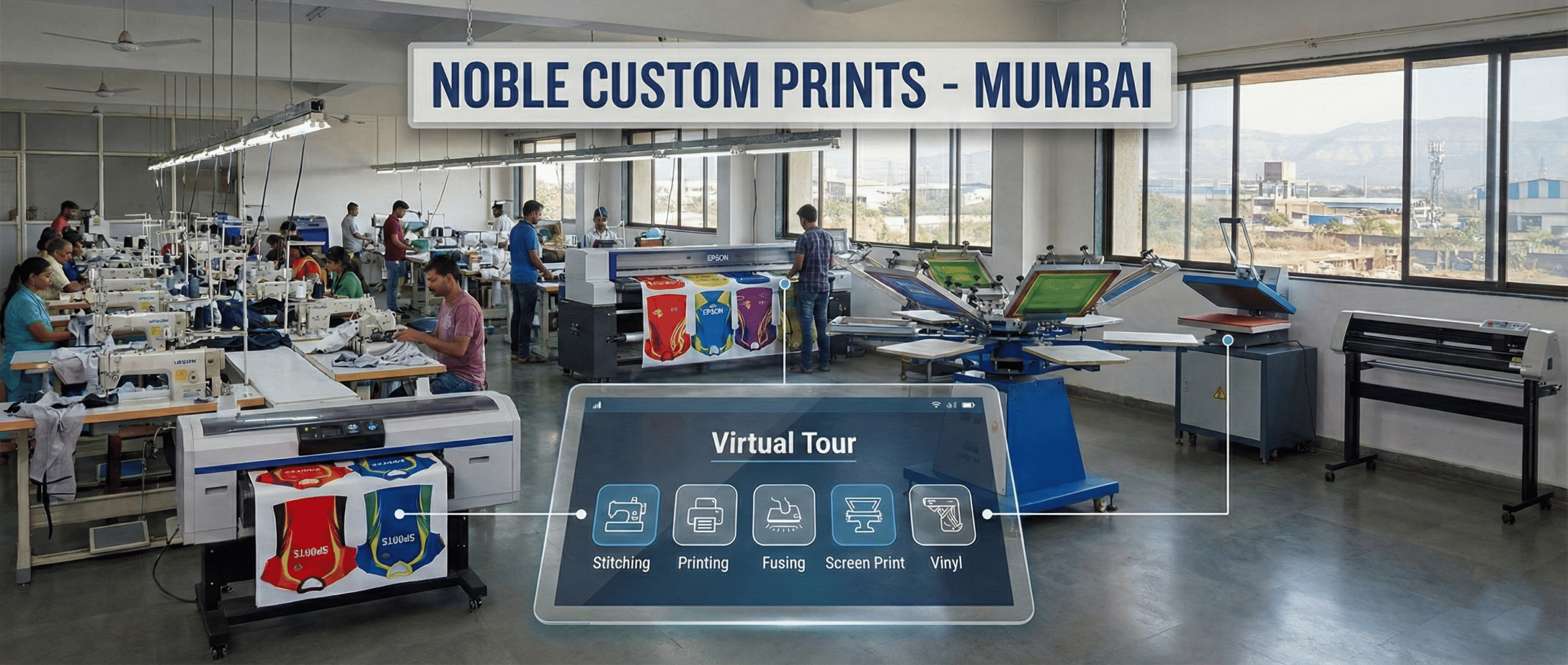

Custom Apparel Factory Tour

Have you ever wondered where your brand’s t-shirts actually come from?

In an industry flooded with “middlemen” and “traders” who operate from laptops, finding a genuine manufacturing partner can be difficult. At Noble Custom Prints, we believe that transparency is the key to quality. That is why we are opening our doors (virtually!) to take you through our production facility in Mumbai.

From the hum of the sewing machines to the heat of the fusing press, here is a step-by-step look at how we manufacture your bulk orders under one roof.

Stop 1: The Cut & Sew Department

Where the fabric takes shape.

Everything begins in our Stitching Unit. Unlike suppliers who just print on ready-made market blanks, we cut and sew our garments from scratch.

- The Setup: Our floor is equipped with industrial sewing machines and large cutting tables.

- The Process: We start with heavy rolls of premium fabric (like our 240 GSM Matty or 180 GSM Cotton). Skilled masters hand-cut the patterns to ensure consistent sizing, while our tailoring team ensures reinforced stitching on every seam.

- Why It Matters: This allows us to control the fit of your corporate uniform, ensuring an XL is actually an XL.

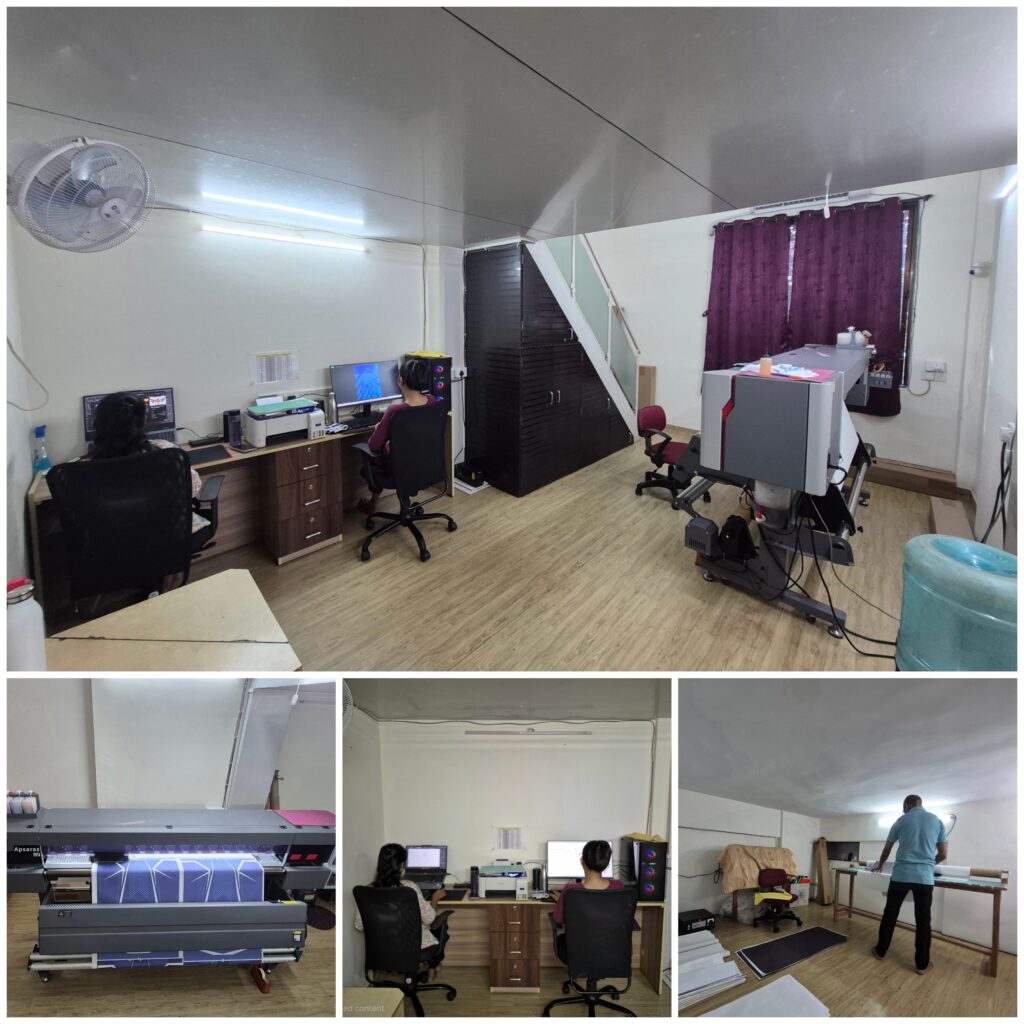

Stop 2: The Digital Sublimation Lab

Where design meets technology.

Next, we move to the Design & Printing Studio. This is the brain of our sports jersey operations.

- The Setup: We run high-speed Imported Sublimation Printers that deliver photo-realistic vibrancy.

- The Process: Our in-house graphic designers prepare your vector files, and the printers transfer the design onto specialized sublimation paper.

- Why It Matters: Because we use genuine Epson technology, the colors on your team kit will match your brand guidelines perfectly—no dull blacks or washed-out reds.

Stop 3: The Fusing Station

Locking in the performance.

A print is only as good as its cure. In our Fusing Unit, we turn temporary ink into permanent color.

- The Setup: We utilize large-format flatbed heat presses and specialized cap-press machines.

- The Process: At 200°C, the sublimation ink turns into gas and bonds permanently with the fabric fibers.

- Why It Matters: This ensures your jersey remains breathable and the print never cracks or peels, even after 100 washes.

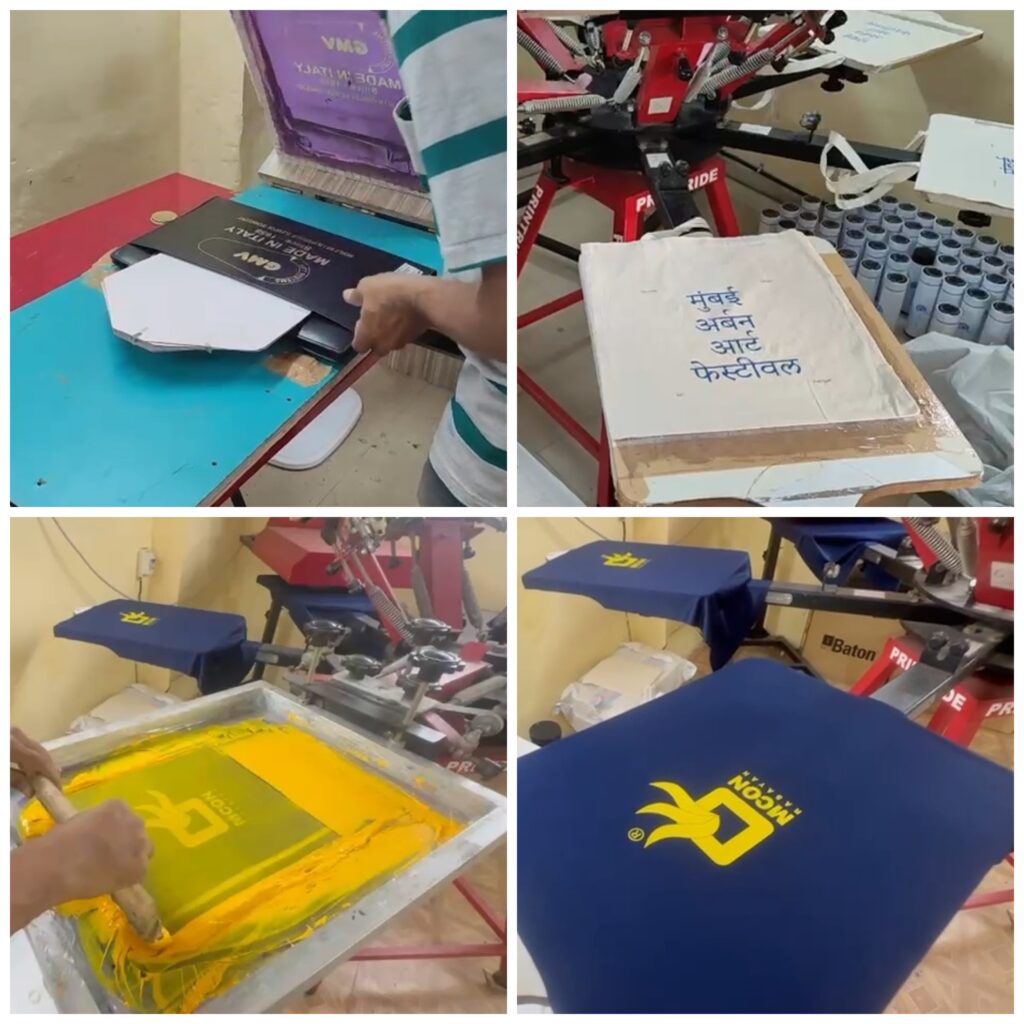

Stop 4: The Screen Printing Carousel

The corporate standard.

For cotton t-shirts and hoodies, we head to the Screen Printing Unit.

- The Setup: Our 6-station manual carousel allows for precision multi-color registration.

- The Process: We push thick, high-opacity plastisol inks through mesh screens to create bold, textured logos.

- Why It Matters: This is the gold standard for durability on cotton fabrics, giving your corporate logos a premium, raised feel.

Stop 5: The Vinyl Studio

Precision in every detail.

Finally, for personalized names and numbers, we visit the Vinyl Section.

- The Setup: We use the Jaguar V LX plotter for surgical cutting precision.

- The Process: After the machine cuts the design, our team meticulously “weeds” (removes) the excess material by hand before heat pressing it onto the garment.

- Why It Matters: This allows us to personalize individual shirts (e.g., “Rahul #10”) without any minimum order quantity constraints.

Come Visit Us for Real!

Photos are great, but seeing the machines in action is even better. We invite all our bulk clients to schedule a visit to our Mumbai workshop. Come touch the fabric, meet the team, and see your order being made.

Ready to start your production with a real manufacturer? Contact Us on WhatsApp or Get a Quote Today